Revox A77 - 41 Years Young

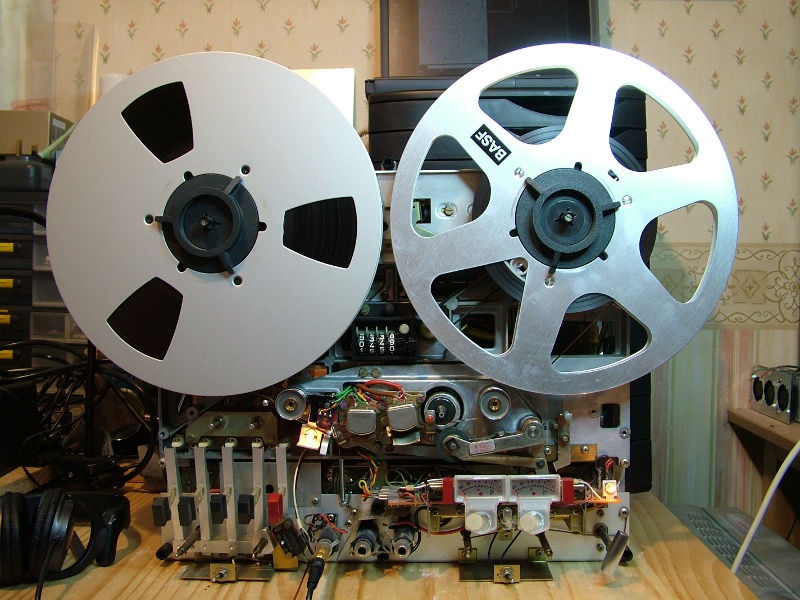

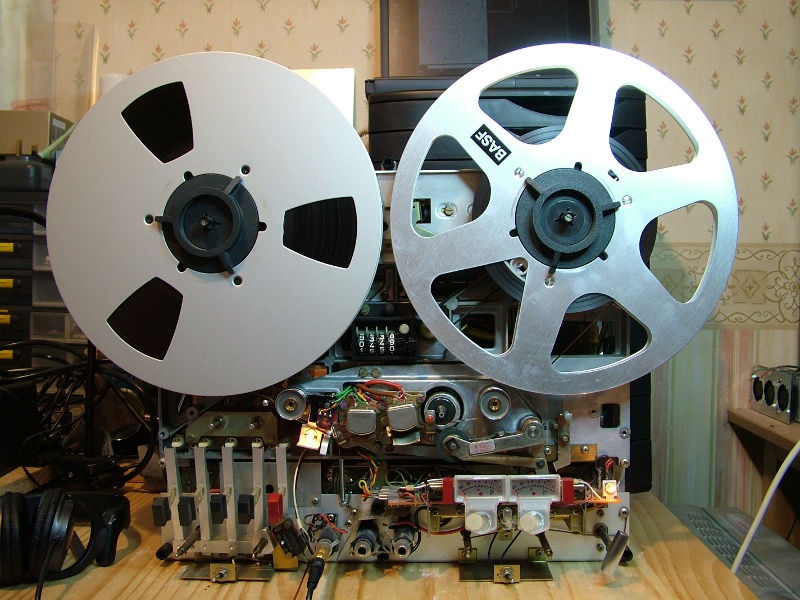

Revox A77 Mk III Dolby with panels removed.

In May 2014 my A77 ground to a halt ... the capstan turned feebly about once on power on

then stopped altogether. Time to take it apart again (the last major overhaul was in August

2007, so that isn't too bad, is it?)

After a bit of thinking and reading the service manual, it looked like a problem on the servo

board was the most likely cause. If the capstan had stopped when the pinch wheel engaged, it

might have been a capstan motor lubrication problem, but stopping with no load after about

one turn didn't fit that. It could have been the capstan motor phase shift capacitor, perhaps.

The usual first step is shotgun replacement of all polarized capacitors. I admit this is a

crude technique, but it very often fixes things. And, once again, it did in this case.

While I was about it, I also replaced the infamous RIFA capacitors with new WIMA equivalents on

the control board and capstan board. In a moment of excess enthusiasm, I also replaced all but one

of the polarized capacitors on the power supply board. The whole transformer assembly

needs to come out to do this. Now - that was a pain in the neck ... Having

all three boards out for service at once involved more disassembly than I was comfortable with,

to be honest. The poor thing had disconnected wires poking out of it everywhere. Would it ever

work again?

Well, yes - it did! And does. Below is a photograph showing the replaced RIFA capacitors (other

renewed bits are not visible).

When reassembling the control board, I managed to get one of the connections wrong. Note carefully

the two green wires on the right most group of connections. The green wire from the reel motor

phase shift capacitor (the other lead from that is red) must go to the right most connector. I managed

to swap those two green wires which made the left hand (seen from front) reel motor not work. Fortunately,

no harm was done.

Re-alignment

Having had it in several dozen pieces, it seemed only fair (and wise) to demagnetize and realign

the machine once it was working again. I described how to do this

here

so I won't repeat it on this page.

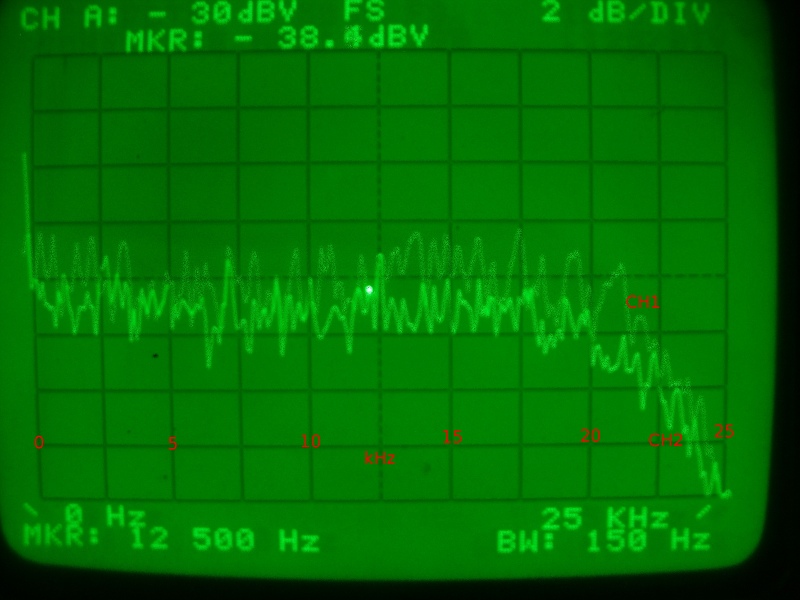

Here are the results of some tests after everything was done ...

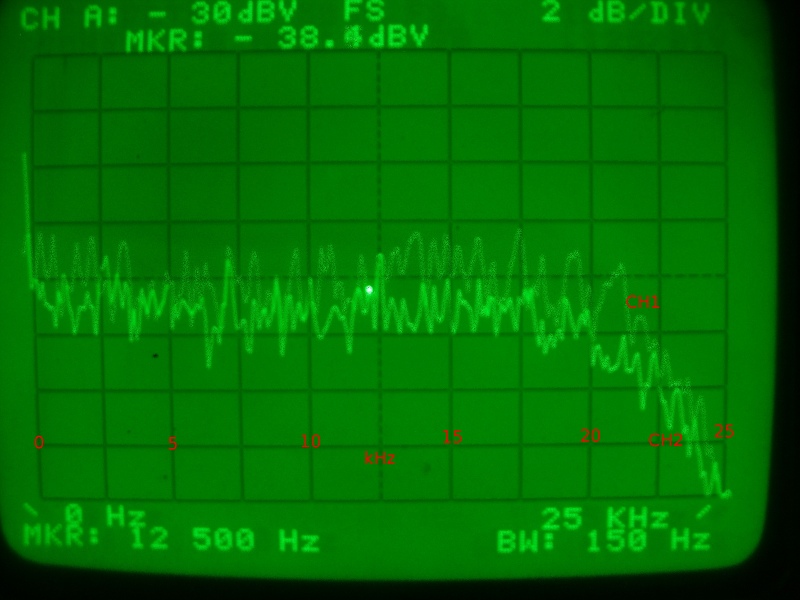

Above is a measurement of the frequency response over 20Hz to 20kHz done with the HP-3582A spectrum

analyzer. Ignore the small bumps - these are an artefact of the technique used by the HP-3582A when

used by an impatient person! Just draw a line through the middle of the "jumpy" trace to see the

response as it really is. Note that one vertical division is 2dB.

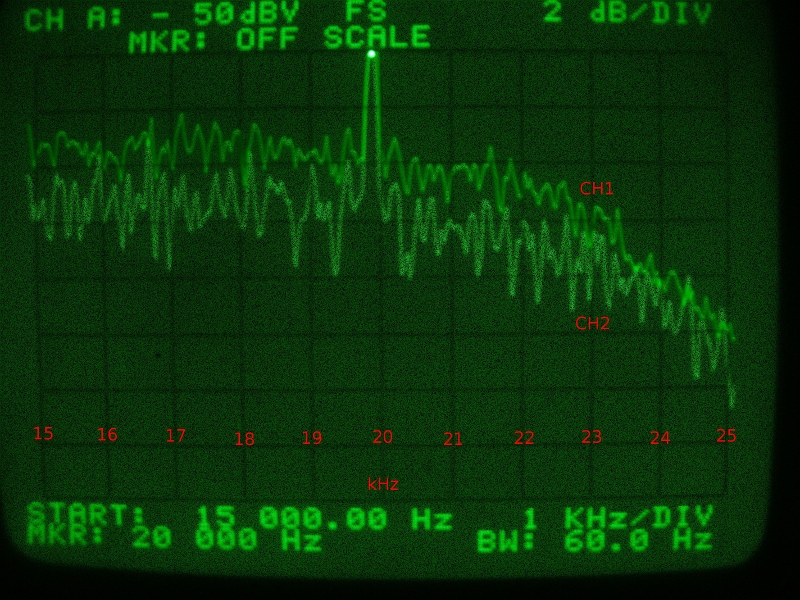

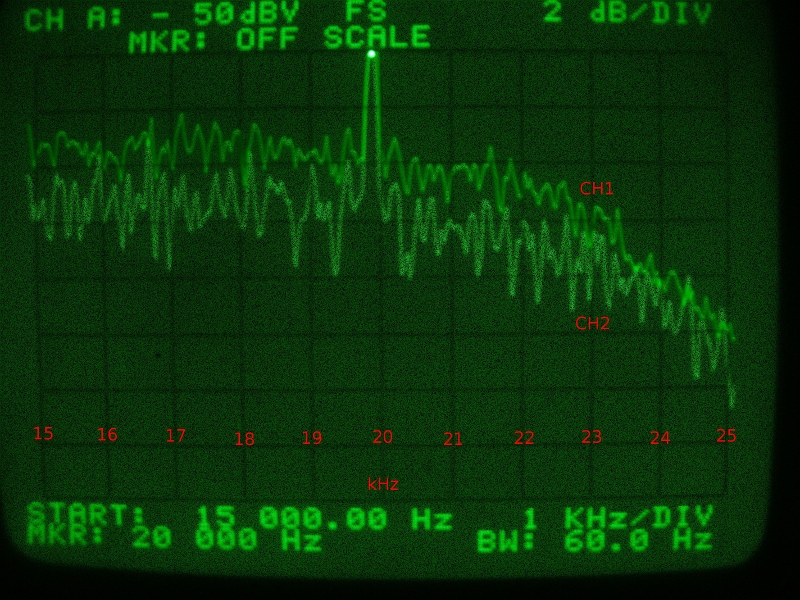

The high frequency part of the response is shown above. That is pretty nice, I think. Basically

flat to 20kHz then a slow fall to 6dB down at 25kHz.

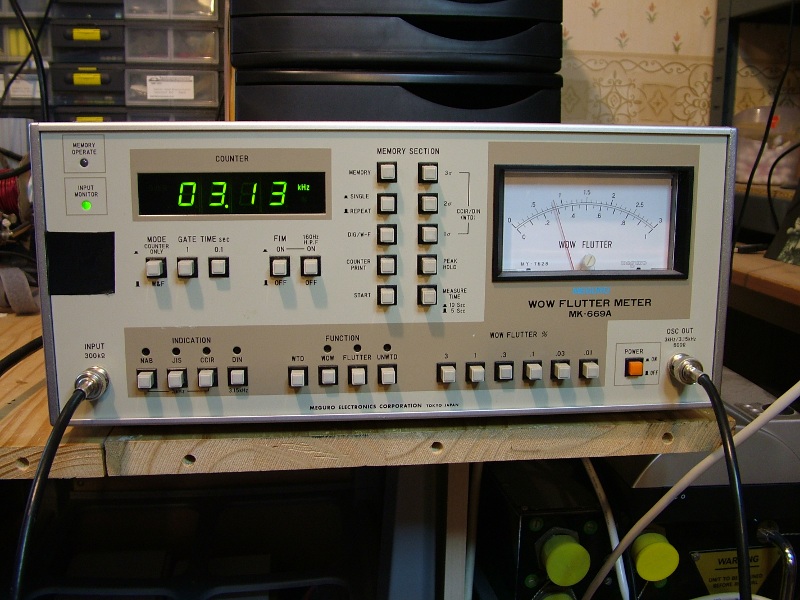

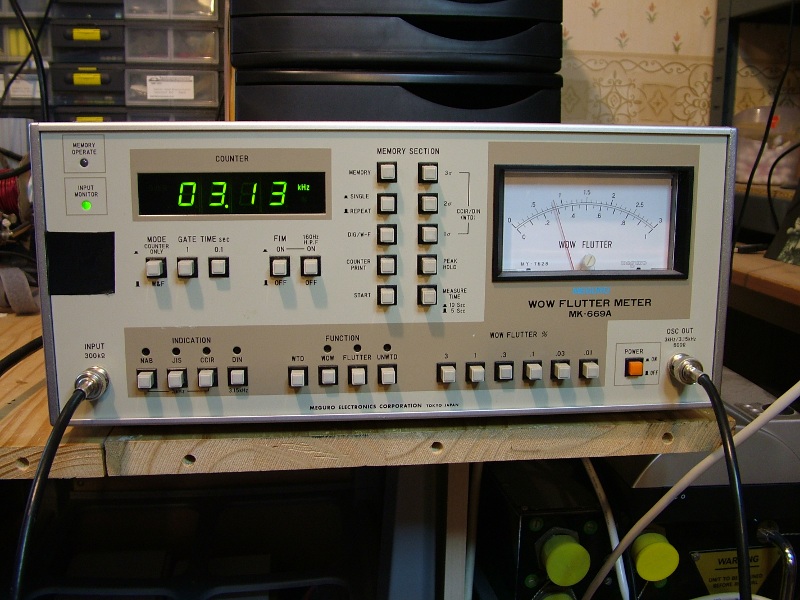

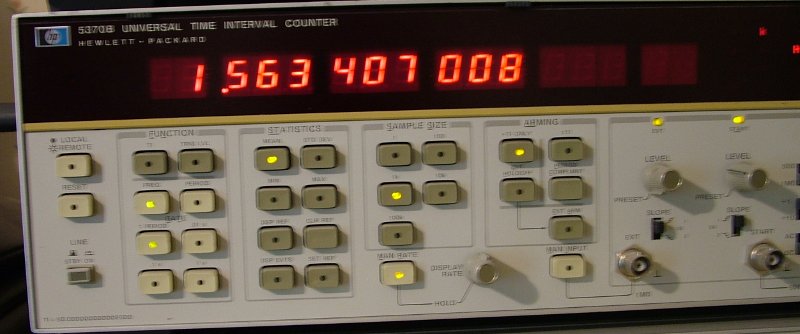

Checking the wow and flutter at 7.5 ips gives the reading shown below.

That is 0.08% ... exactly to the original specification!

Even though I had the beast in (too) many parts at one point, I didn't run it with the servo

board out so that speeds could be adjusted. This seems to me to be a really painful procedure

and once again I chickened out. So the speeds are still not exactly right (although they are

close and it really doesn't matter if recordings are played back on the same machine). The

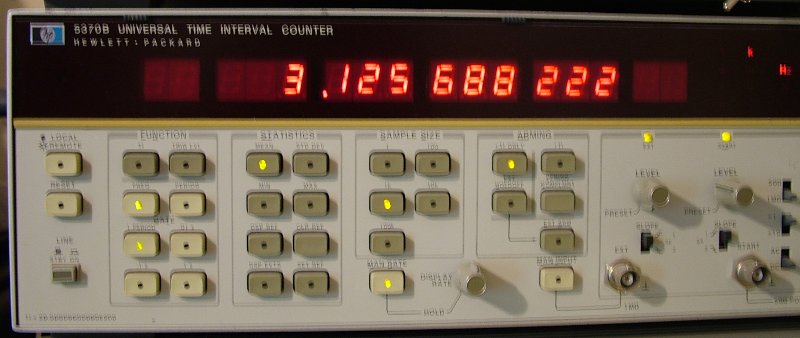

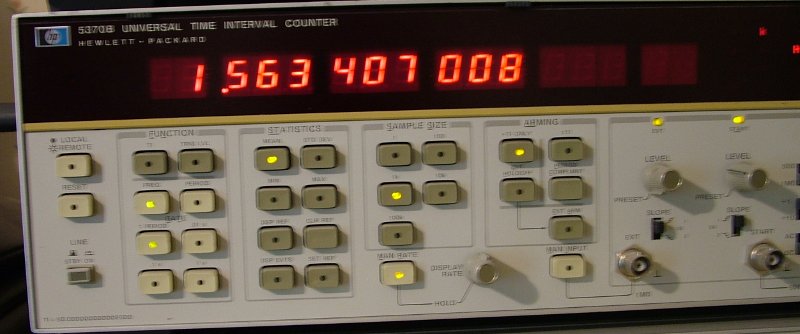

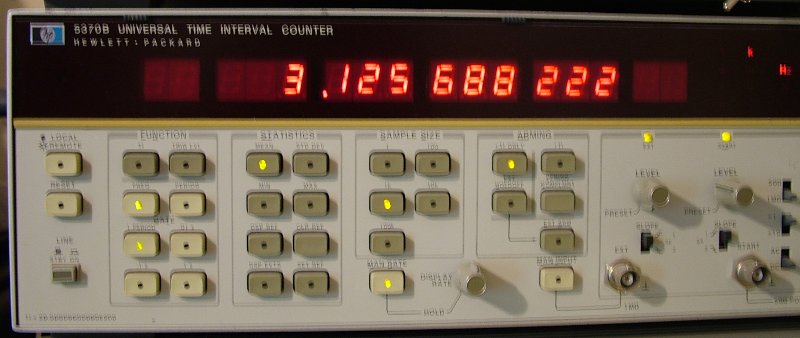

pictures below show the frequencies reproduced when playing a 3150Hz test tape at 7.5 and 3.75 ips.

They should be 3150Hz and 1575Hz, so 7.5 ips and 3.75 ips are both running at 99.2% of the correct speed.

The specification says +/-0.2% for speed, so -0.8% is out of spec. Maybe one day I will risk running it

with the servo board dangling out the back ... But it still sounds great and I'm not planning on

replaying tapes other than those recorded on it, so it will do for me.

I wonder which of my latest gadgets will be still working, maintainable and in spec 41 years from

now? Well, I won't be around to check, that is for sure!

Go home ...